Plant Features

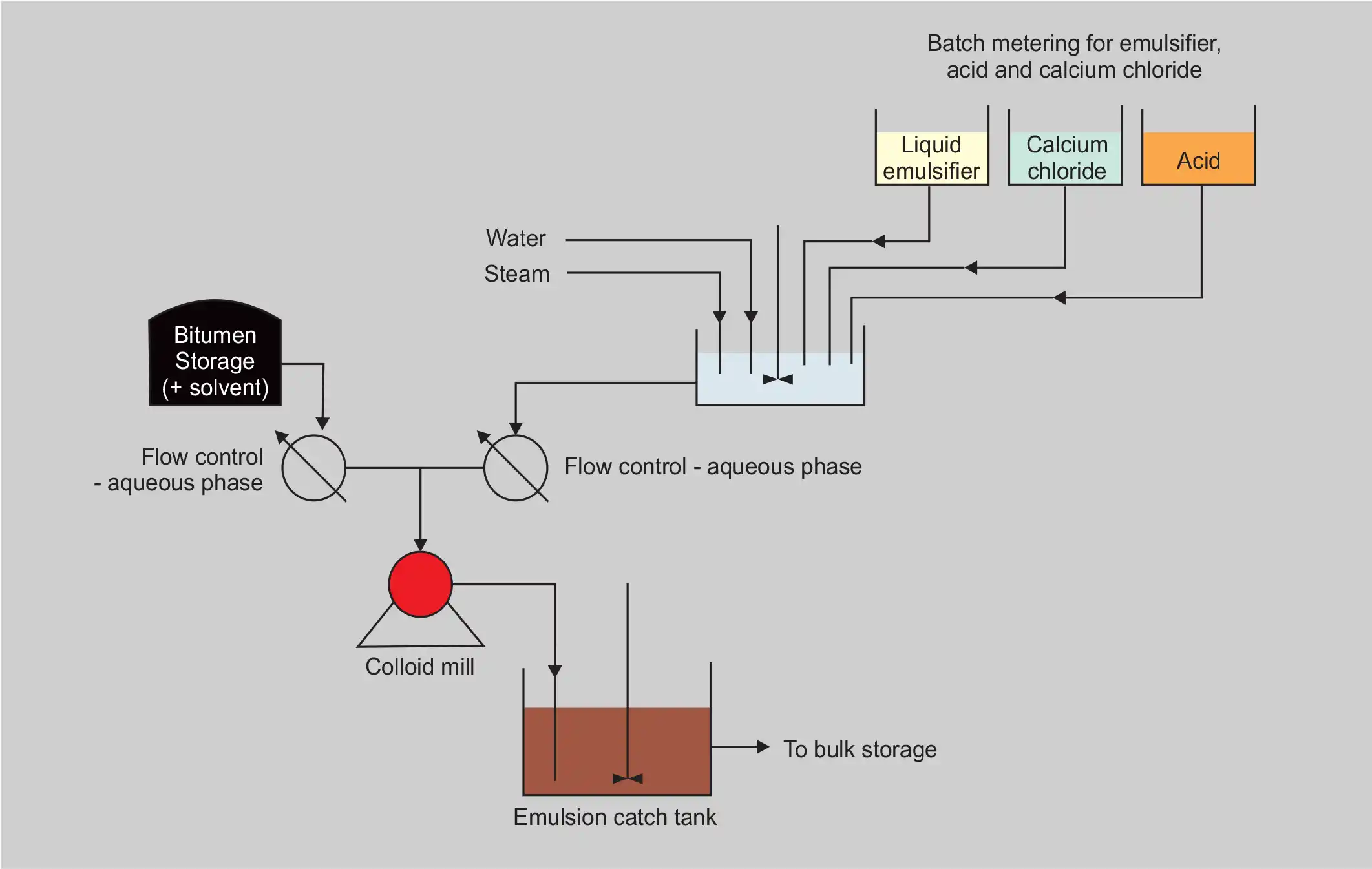

The facility offers bulk bitumen storage tanks with appropriate temperature sensors and gauges along with a fully automated emulsion mill of 7.5 MT per hr. capacity. The facility offers bulk emulsion storage tanks and a packing unit which offers the promise of “Q&Q” to the fullest extent, both for bulk and packed users. This facility also offers value added bitumen for specified users. A fully equipped laboratory supports engineers to evaluate quality levels for every batch roll out.

Delivery Promise

- Round the year availability of stocks.

- Consistent quantity and quality (Q&Q) for every load.

- Hassel free commercials ensures minimization of lead time.

Surfacing vis a vis flexible pavement

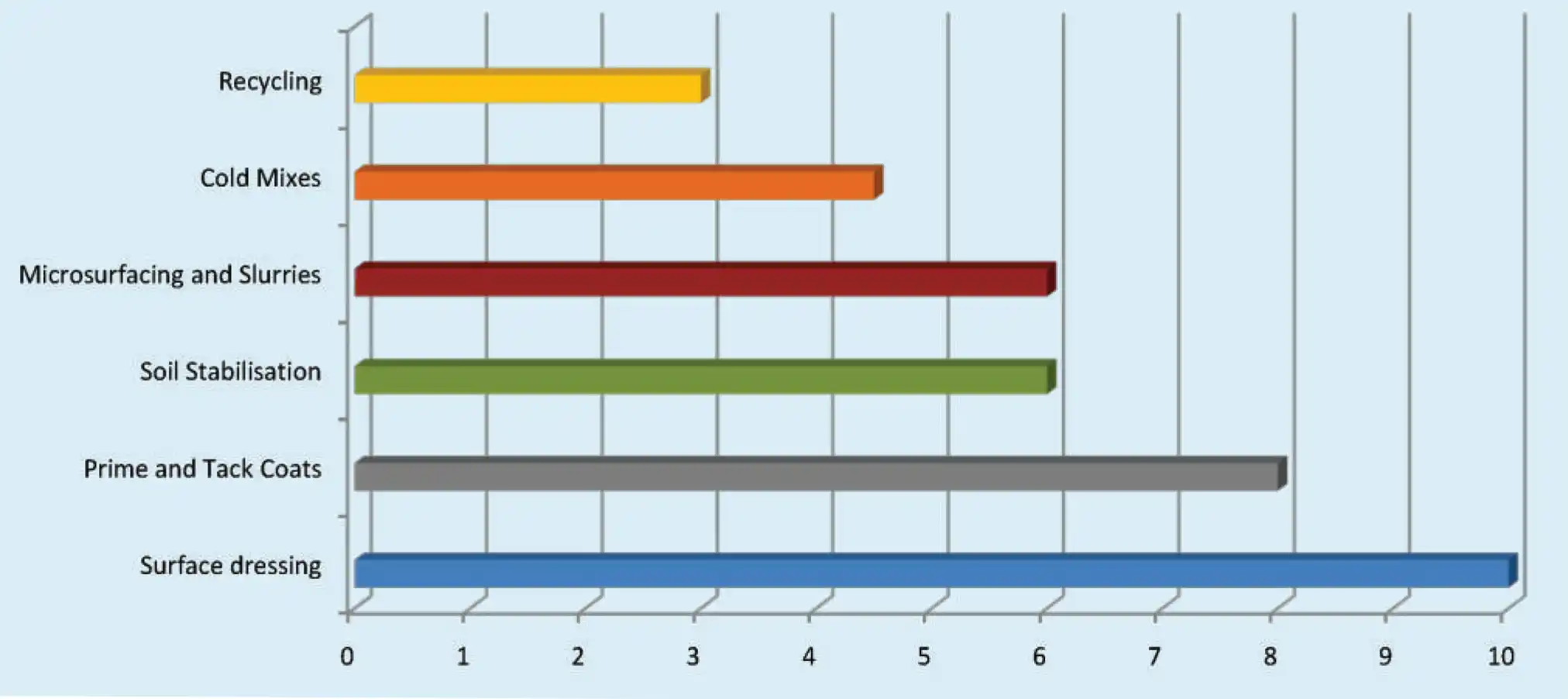

The surfacing consists of two layers. The lower layer is termed the ‘binder course’. Its primary function is to distribute the stresses from the surface course to the base without over stressing. It also provides a layer with good surface regularity upon which the surface course can be constructed. The tolerance at the top of the surface course is often 6 mm from the design levels.

The upper layer of the surfacing is termed the surface course. It is this layer and this layer only that is visible to the road user. The surface course has to meet a formidable list of requirements. It must :

- Resist deformation by traffic

- Be durable, resisting the effects of wheather, abrasion by traffic and fatigue

- Provide a skid-resistant surface

- Generate acceptable levels of noice

- Provide a surface of acceptable riding quality

- Except in the case of porous asphalt, be impervious thus protecting the lower layers of the pavement

- Contribute to the strength of the pavement structure

- Generate acceptable levels of spray.

Health and safety

Emulsions are unlikely to present any significant health or safety hazard when properly used in the recommended application and good standards of industrial and personal hygiene are maintained. Avoid contact with skin. Use protective clothing i.e. coveralls, gloves, boots, neck and face protectors.